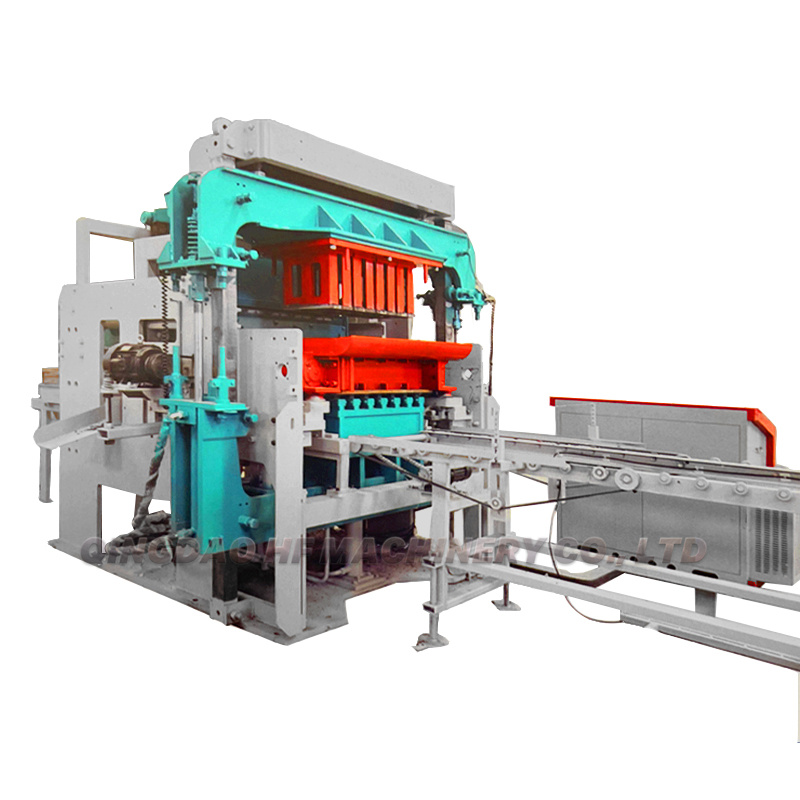

The functioning of the blocks-making device is built around the vibration and the compression of the concrete. They are equipped with a hopper which they can store and receive the freshly poured cement needed for the creation of blocks. The cement is dosed into the mould to the appropriate quantities. In order to make it easier to fill every mould as well as the mould are both vibrated as is the shaker.

After this process is completed after which the mould is compressed to its exact dimensions as well as the air which forms in between the grains of sand and gravel is eliminated. In the end, it is vibrated again to aid in it compress (harder than the time when it was filled with mould).

At Qingdao HF block machine, we offer a variety of presses that consists of 5 models. They can all work with metal, plastic or wooden production trays that are of various dimensions, and are included in an assembly line that is which can be outfitted with different options (for transfer of products and palletisation, for example.) to satisfy the needs of each customer.

We are now going discuss the working that we have in these Block-making Machine models. We will begin by separating semi-automatic, automated or manual blocks machines. In the case of a manual machine, it's the machine that is moving and occupies too much space within the factory.

In the semi-automatic and automatic models, it's the traytrays that move. This makes it easier to complete the process of production and assists to increase the production capacity. Block machines from our Block machines are designed and constructed to produce concrete block of various types and dimensions.

They've been growing rapidly, starting from the initial that were simply metal molds where the mixture was naturally made and then to the ones we offer today that can perform all the work completely automatically. They also have excellent production rates, with low maintenance costs and can adapt to the demands of our diverse clients.

With the various kinds of block machines, there are various options. For instance the installation circuit could be set up as a line or an U that has five-height elevator and descender units which facilitate the transfer of the tray to dryers with the help of the forklift truck. For palletizing, the machine could be equipped with a pneumatic or an automatic palletiser, and so on.

However, an blocks-making machinery is also equipped with different components or mechanisms, such as the The mould, which is vibrating, with various cavities that allow for varying the dimensions and the type of concrete blocks that are made and the plates for compacting, and so on.

Also, there is the base where you can put the rails, the springs as well as a carriage to carry the compactor. The two options that provide lower maintenance costs, and need less installations, yet nevertheless provide large productions.

When it comes to purchasing machinery for your business, trust and confidence are key factors in making a decision. At HF Machinery, we understand the importance of providing high-quality products and exceptional customer service to ensure our customers a

In today's rapidly changing business landscape, making informed investment choices is crucial for securing future success. As industries evolve and technologies advance, opportunities arise for forward-thinking investors to capitalize on emerging trends.

In today's fast-paced and dynamic business environment, companies need to be agile and adaptable to survive and thrive. Qingdao HF Machinery Co., Ltd., a leading manufacturer of brick making machines, understands the importance of staying ahead of market

Whether for inquiries for inspections and

maintenance, for individual plant optimizations or

extensions, or spare and wear parts.

Our after-sales service is at your disposal for all

questions

We will contact you within 24 hours.